Feb 27, 2019

EPI Employees Get Certified, Improve Processes

Elkhart Plastics’ (EPI) South Bend, Ind., the plant has new processes in place that increase productivity and decrease costs after four employees got certified through the Purdue Manufacturing Extension Partnership’s (MEP) Team Member Lean Certificate Training and Lean Practitioner Implementation Certificate programs.

The program provides employees of manufacturing companies with training on ways to improve performance by removing waste and improving processes. A grant from South Bend Mayor Pete Buttigieg’s Pathways on Demand Workforce Development Program funded the program. Learn more about the training.

EPI employees Ty McClurg, training coordinator; Carnell Campbell, machine oven operator; Shatoria Adams, secondary processor; and Kenneth Garrett, oven operator, were selected by company management to participate in the program.

Lean Manufacturing

McClurg, Campbell, Adams, Garrett, and seven employees from other plastic manufacturing companies in the South Bend area spent 10.5 days over two months completing Team Member Lean Training and the courses necessary to obtain their Lean Practitioner Implementation Certificates. Participants learned analysis skills, problem-solving techniques, project management, the principles of lean manufacturing, and more on the training.

“This class has really raised my level of thinking to be better able to recognize and fix problems,” McClurg says.

His colleagues and classmates agree that the program was impactful.

“Learning and brainstorming with everyone else in the group was the best part because everyone had so many different ideas,” Adams says. “It’s amazing how we could all come together even though we’re from different companies and help each other find ways to improve.”

“Working second shift, I’d never seen the processes or the people that make things work on first shift, so it was amazing to work with them,” Garrett says. “This has changed my way of thinking so I can make my area of the company better, and that helps out everybody.”

“I still have a lot to learn. But, with this program, I met a lot of nice people and have gotten a lot of great information,” Campbell says. “It’s opened my eyes to a lot of different things.”

Lean Implementation Certificate Projects

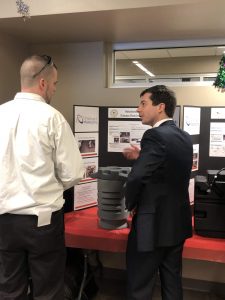

The program culminated in December 2018 with the Lean Practitioner Implementation Presentation Event at EPI headquarters in South Bend. During this event, practitioner participants presented the business improvement projects they had completed to their managers, colleagues, and community representatives.

McClurg and Campbell shared their joint project on improving the rotational molding process flow. Adams and Garrett explained their plan to improve the product flow for DEF Tanks.

Participants from other manufacturing companies including Hoosier Molded Products, SPI Industries, JMS Engineered Plastics, and General Stamping & Metalworks presented projects on improving changeover times, workflow improvement, and reducing machine set-up time.

Mayor Buttigieg also attended to engage with participants about their projects and hear the outcomes of the city-funded program.

Since the training, EPI employees have continued to use the skills they gained to explore ways to make improvements for the greater good of the company.

“I’m thrilled about the impact this program has on our employees,” Mike Bauman, EPI South Bend plant manager, says. “Programs like this empower employees and give them knowledge, and they now have the tools they need to take an idea and put it in motion. I see employees on the floor brainstorming about what we’re going to do to make tomorrow better than today, and that should be celebrated.”

About Elkhart Plastics

Elkhart Plastics is a 31-year-old company that creates rotationally molded products in an almost endless variety of shapes, lengths, and thicknesses out of its six facilities. The company provides custom designs for clients in industries including recreational vehicles, marine, agriculture, commercial construction equipment, heavy truck equipment, material handling, and more. EPI also manufactures Tuff Stack™ and Tuff Cube™ Intermediate Bulk Containers, Connect-A-Dock, and KONG Coolers.